The eROBUSTO Master Modules provide you with powerful CODESYS V3 programmable controllers. With CODESYS you program the IEC 61131-3 control code, configure your I/O's and the WEB visualization. Fieldbus interfaces such as Ethernet, Profinet, EtherCAT or CAN are available for expansion. Our eROBUSTO Slaves are used for decentralized inputs/outputs. They allow powerful networking via CANopen.

A triple Ethernet switch and a gigabit port, as well as collection, processing and compression of digital and analogue signals via CODESYS: eROBUSTO is simply an ideal gateway for your plants!

To monitor operating and quality values, your process data can be directly stored in or retrieved from CODESYS in a local or decentralized database via SQL.

With its aluminum continuous casting profile, eROBUSTO has an extremely robust and attractive design. The perfect combination of mechanics and electronics offers optimum performance without active cooling - and with minimal power consumption.

CODESYS combines classical PLC programming with all the possibilities of a professional development and setup software for automation devices. Without additional tools, the entire application can be configured, programmed, tested and commissioned on a single interface.

With our libraries, you can easily modify and adapt the fieldbus configuration as well as the assignment of the digital and analog inputs and outputs during the runtime of our PLC.

Keep an eye on your production. With our controls, the digital and analog data from the field level can be sent to the cloud via an MQTT extension. In this way, the data can be evaluated and visualized independently of the location, thus increasing production's efficiency.

As we use the latest electronics solutions with MultiCore support, you have the maximum performance available on a minimum of space.

For powerful HTML5 visualization on the latest web standards we provide a high-performance communication interface on the controllers for exchanging control variables. There are no obstacles in the way of your CI and a modern system visualization.

The controllers incorporate VHDL-programmable modules, which enable processing times in the microsecond range to be achieved. The result is a high-performance reaction time at the plant and therefore a shorter production time for your products.

For reliable control sequences in your process, analog values can be quickly recorded, evaluated and archived in 16 million step resolution.

A variety of different sensors can be evaluated with our analog inputs and outputs. You can easily specify the sensor via the PLC program.

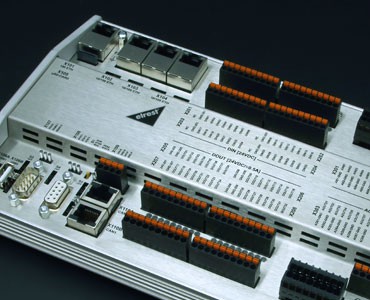

A high degree of functionality is available in a very small space due to the special arrangement of the interfaces as well as the inputs and outputs.

With eROBUSTO we offer you a high-quality and robust master-slave system. The sophisticated mechanical concept ensures optimum heat dissipation even at high power levels. A wide variety of processor modules offer flexible solutions with a very high packing density and a large number of analogue inputs or outputs.

The control program as well as the visualization of the master modules is programmed in IEC 61131-3 code via CODESYS V3. By using a WEB server for the visualization, the systems fit seamlessly into your existing IT infrastructure and enable you to create modern solutions designed in your CI.

combo CM1xx

The compact mini controller in the lower price segment is the ideal entry into the world of programmable controllers.

Based on the operating system µE, simple to medium tasks in the area of control and visualization can be implemented. Fieldbuses and integrated I/Os are available for this purpose.

combo CM2xx

For high performance in a compact design, this combo offers an optimal solution in the smallest space.

Flexible solutions can be implemented with various WEB visualisations, control with motion functionality, fieldbuses, integrated I/Os and the embedded CE6 operating system.

Integrated Soft-SPS

Freely programmable according to IEC 61131-3 / CODESYS

Expandable by combo slave extension module

Onboard programming, diagnostic and communication interfaces such as Ethernet, CAN, RS-232/RS-485

Remote maintenance via modem and Ethernet

Integrated web server, optionally CODESYS

Visualization options via: visio terminal and / or visio control operating system or visio Web via Internet Explorer